Dublin gas works provide gas boiler installation, replacement, and upgrade services in Dublin and nearby areas.

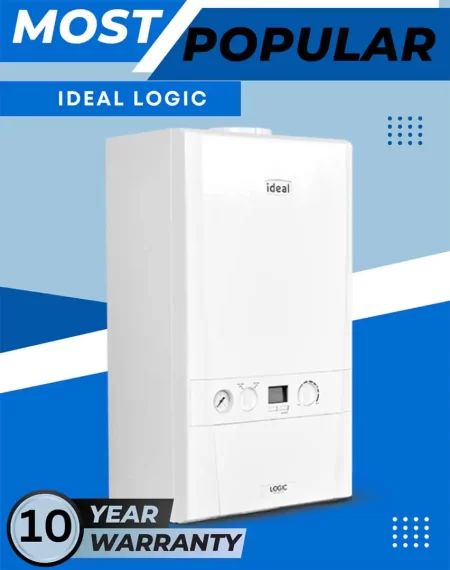

We have more than 40 years of experience with boiler installations, service, and maintenance. We install new gas boilers from all the major brands like Worcester Bosh, Viessmann Boilers, Ideal Boilers, Baxi Boilers, etc.

Our Qualified and RGI-registered Plumber will advise what best suits your needs. So what are you waiting for, Call us Now.

Find a boiler that is perfect for your home, at a price that is right for your budget and needs.

Yes, it is often worth replacing an old gas boiler. Old boilers are less efficient, which means they use more energy and cost more to run. This can lead to higher energy bills and a bigger impact on the environment. Newer boilers are more efficient and can save homeowners money in the long run. Additionally, older boilers are more prone to breakdowns and can be more costly to repair. Older gas boilers may not have the same safety features as new boiler models, such as automatic shut-off valves, which can help prevent gas leaks and other hazards. Replacing an old gas boiler with a new, more efficient model can improve the comfort of your home and provide peace of mind knowing that your heating system is reliable and up-to-date.

It is not recommended to install a gas boiler yourself, as this can be dangerous and may not comply with regulations. It is recommended to hire a professional installer who is RGI registered and qualified to carry out gas boiler installations.

Dublin gas works have 40 years of experience in fulfilling Ireland’s heating needs and professional RGI registered technicians ready to serve customers any time.

The installation time for a gas boiler can vary depending on the complexity of the installation and the type of boiler being installed. But a normal household boiler installation can be completed in one day. It is recommended to consult our professional team to get an accurate installation time.

The cost of a new gas boiler Ireland can vary depending on factors such as the size of your home and the type of boiler you choose and the complexity of the installation. An average gas boiler installation cost in Ireland is between €2500 and €4000 in 2023. For a more accurate price, it is recommended to get a quote from a Dublin gas work professional installer.

If your 15-year-old gas boiler is still functioning well, it may not be necessary to replace it immediately. However, as boilers age, they become less efficient and require more frequent repairs, which can ultimately cost more in the long run. Additionally, newer boilers are often more energy efficient, which can result in lower heating bills. It’s recommended to consult with our qualified heating engineer to assess your specific situation and provide recommendations on whether it’s worth replacing your old gas boiler.

The average lifespan of a gas boiler is between 10 to 15 years. However, with regular maintenance and servicing, it is possible to extend the lifespan of a boiler. It is important to keep in mind that an older boiler may not be as energy-efficient as newer models, which could result in higher energy bills. Therefore, it may be worth considering replacing an older boiler if it is not operating efficiently or if repairs are becoming frequent and costly.

With 40 years of experience in serving our customer’s needs be it – Gas or Oil boilers, Heat Pumps, Central Heating, Bathroom Refits, and General Plumbing Maintenance.

Unit B2 Riverview Business Park Nangor Road, Dublin, D12 TN99

(01)4298666

dublingasworks@gmail.com

Monday – 8.00 – 17.00

Tuesday : 8.00 – 17.00

Wednesday : 8.00 – 17.00

Thursday : 8.00 – 17.00

Friday : 8.00 – 17.00

Saturday : Closed

Sunday : Closed

Copyright © 2025 Dublin Gas works Developed By NH Consultants

By using this site you accept the terms of use. | Refer here for our Privacy Policy